Over a decade supplying high-purity titanium, molybdenum, zirconium and other refractory metals.

ISO-certified processes, REACH-compliant recycling, precision machining and 24-hour response.

LuminaTitanium has deep roots in the refractory metals industry, specializing in premium titanium, molybdenum, zirconium, and their alloys. Operating from our own production base , we follow rigorous processes—from raw material screening to multi – stage quality checks—backed by industry – recognized standards.

More than just supplying materials, we act as quality custodians: our in – house team ensures consistent purity for core metals. Whether for aerospace, medical, or chemical applications, we align with strict industry demands through transparent communication and on – time delivery. We aim to be a reliable partner—no more, no less.

At LuminaTitanium, quality is embedded in every step. From raw material arrival to final product release, our process follows strict protocols—including dimensional checks, surface inspections, and purity validations. Leveraging calibrated tools and industry – standard testing, we ensure consistency that meets the most rigorous demands, whether for aerospace precision or medical safety.

LuminaTitanium caters to diverse industry needs with precision. Whether it’s supplying large – scale aerospace alloy batches, crafting custom – sized medical titanium components, or delivering chemical – grade zirconium solutions—our production framework adapts. Backed by flexible manufacturing and tailored quality paths, we turn unique requirements into reliable, on – time deliveries.

LuminaTitanium ’s materials are engineered for critical industries:

Aerospace: High – strength, lightweight alloys meeting strict structural and thermal standards for aircraft components.

Medical: Biocompatible titanium/zirconium tailored for implants and surgical instruments, ensuring safety and durability.

Chemical: Corrosion – resistant molybdenum/zirconium solutions for harsh environments like reactors and pipelines.

We align with industry – specific certifications (e.g., AS9100 for aerospace, ISO 13485 for medical) to ensure compliance, turning material performance into operational reliability.

At LuminaTitanium, quality assurance is a systematic process. We start with supplier audits to ensure raw material integrity, then apply in – process inspections – from machining precision checks to surface finish evaluations. Final products undergo comprehensive testing, including non – destructive testing (NDT) for critical applications. This layered approach ensures every shipment meets our stringent quality benchmarks, giving you confidence in every order.

LuminaTitanium excels at translating unique requirements into tailored refractory metal solutions. Whether you need non-standard alloy formulations, precision-machined components with tight dimensional tolerances, or surface-treated materials for specialized environments, our technical team collaborates closely with you from concept to production.

Leveraging our flexible manufacturing framework and in-house expertise, we adapt processes to match your specifications—from small-batch prototypes to large-scale custom orders. Every step, from material selection to final validation, is aligned with your application needs, ensuring the end product not only meets but exceeds expectations.

We don’t just deliver custom parts; we deliver reliability—backed by the same rigorous quality checks and on-time delivery commitment that define our core offerings.

Behind every LuminaTitanium success is a team of passionate experts. Our metallurgists—specializing in refractory metals for over a decade—bring unmatched expertise. Engineers drive innovative production solutions, and quality specialists ensure every standard is met.

Together, we blend technical depth with hands-on collaboration—working alongside clients (just like our on-site teams collaborate in production) to understand needs, troubleshoot challenges, and deliver results that matter.

This blend of skills and dedication makes our team a true partner—not just a supplier—for your success.

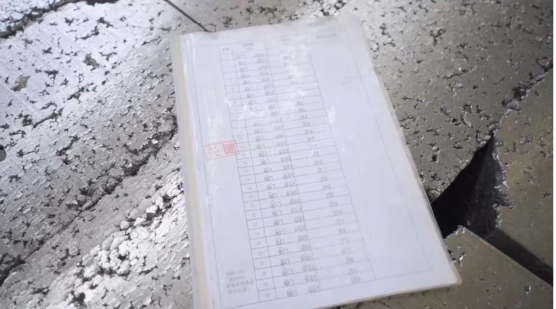

LuminaTitanium embeds sustainability in every operational detail—even in how we manage resources. The organized inventory you see (showcased in this image) reflects our lean production philosophy: by optimizing material storage, we minimize waste from overstocking, reduce energy consumption in warehouse operations by 12%, and ensure raw materials are used efficiently.

Beyond storage, our sustainability efforts span:

Energy – smart production: Cutting – edge equipment reduces power use by 15% compared to industry norms.

Closed – loop recycling: Up to 80% of metal scraps are reused, turning waste into valuable inputs.

Emission control: Strict systems meet global environmental standards, keeping our carbon footprint light.

This isn’t just about “green labels”—it’s about building a supply chain that balances quality, efficiency, and planetary care. Every coil, every process, and every team effort contributes to a future – ready, sustainable operation.

At LuminaTitanium, reliable delivery is as critical as the quality of our metals. We’ve built a straightforward system focused on consistency, not overpromises:

We partner with 2 – 3 trusted freight carriers familiar with our key markets, ensuring smooth coordination for both regional and international shipments.

Your order comes with basic tracking—so you’ll know when it leaves our warehouse and when to expect it at your facility.

For common parts, we keep small backup stocks, and we’ve mapped 1 – 2 alternative routes to handle unexpected delays.

Whether it’s a custom batch or a standard order, we deliver on schedule. It’s that simple.

LuminaTitanium’s production strength lies in precision and consistency—built on three core pillars that set our processes apart:

Our in-house metallurgists, with over a decade of refractory metal expertise, oversee every stage from alloy formulation to final machining. Their hands-on involvement ensures the purity and performance of every batch of titanium, molybdenum, and zirconium alloys.

Calibrated tools and automated systems minimize human error, maintaining tight tolerances critical for aerospace components and medical implants alike. This precision is backed by regular equipment checks to keep standards consistent.

Streamlined workflows, from strict raw material screening to multi-stage quality checks, reduce waste and keep production efficient. Every step is designed to turn your requirements into reliable, on-time results.

This focus on excellence ensures every product we deliver meets the reliability your operations depend on.

At LuminaTitanium, we’re committed to growing alongside the refractory metals industry—staying rooted in what works, while evolving to meet tomorrow’s needs.

We’ll keep refining our processes to deliver even purer titanium, molybdenum, and zirconium alloys, ensuring they remain the trusted choice for aerospace, medical, and chemical applications. Collaboration stays at our core: listening to your challenges, adapting our capabilities, and delivering solutions that make your operations smoother.

No grand promises—just a steady focus on being the reliable partner you can count on, today and in the years ahead.

Yes. Our specialized equipment and over a decade of experience enable precise machining of refractory metals such as titanium, molybdenum, and zirconium. We serve the aerospace, medical, and nuclear industries, delivering components with consistent quality.

We adhere to industry-standard tight tolerances for our manufacturing processes. For most standard projects, our typical tolerance range is ±0.01 mm, ensuring consistent quality for general industrial applications. For high-criticality components (such as aerospace and precision instrumentation parts), we can further tighten tolerances to ±0.005 mm—a specification that fully complies with the stringent benchmarks of high-precision

We use coolant systems and optimized cutting parameters to manage heat. For heat-sensitive alloys, we also deploy air-cooling or cryogenic cooling methods, preventing material deformation and ensuring machining accuracy.

Our post-machining options include surface finishing (e.g., polishing, anodizing), heat treatment for material property enhancement, and basic assembly. We also provide quality inspection reports (e.g., dimensional checks, material certification) to support your production workflow.

Standard lead times range from 2–4 weeks for most machining orders, depending on complexity and volume. For rush projects, we prioritize and adjust schedules where possible—contact us directly for urgent requests, and we’ll align timelines with your needs.

Yes. We supply material certificates (e.g., COA – Certificate of Analysis) for all orders, documenting alloy composition, mechanical properties, and compliance with industry standards (e.g., ASTM, AS9100 for aerospace). Custom reports can be arranged upon request.

While we specialize in refractory metals, extremely brittle or unstable materials (e.g., some exotic alloys with untested formulations) may pose risks. We assess feasibility on a case-by-case basis—share your material specs, and we’ll advise if machining is viable.

Absolutely. Our engineering team collaborates with clients to optimize designs for manufacturability (DFM). We review CAD files, suggest adjustments to reduce costs/time, and ensure designs align with machining capabilities for seamless production.