Cut-To-Length Services for Rods, Bars & Tubes

Custom Cut-To-Length for Practical, Ready-to-Use Metal Components

LuminaTitan provides cut-to-length services for rods, bars, tubes, and pipes in titanium and other special alloys, based on the sizes and drawings you specify. Parts are prepared for easier machining, welding, assembly, or sampling—ideal for buyers who want usable lengths without investing in in-house cutting capacity.

Service Capabilities

Versatile Shape Cutting

- Round, square, rectangular, and simple custom profiles

- Lengths processed according to your project or drawing requirements

Multi-Material Support

Cutting services available for:

- Titanium and titanium alloys

- Stainless steels

- Aluminum

- Copper, brass and selected nickel/special alloys (on request)

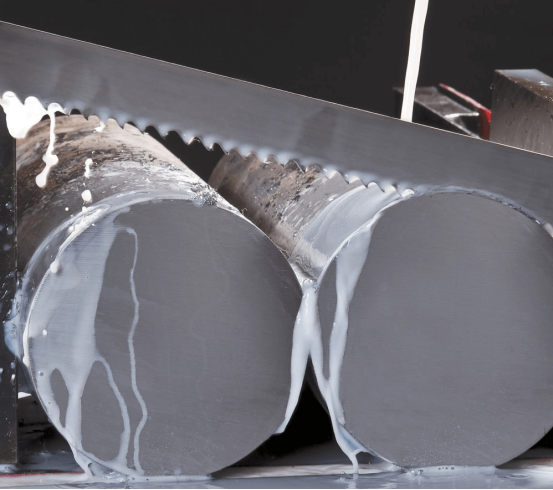

Clean, Consistent Ends

- Straight cuts suitable for further threading, welding, or clamping

- Burrs reduced for safer handling and smoother downstream operations

Titanium Cutting Focus

Titanium is one of LuminaTitan’s core materials. Cutting is arranged with suitable blades and parameters to provide:

- Stable cutting without excessive heat influence on the ends

- Reduced burr formation to simplify secondary machining

- Practical length accuracy discussed and confirmed at quotation stage according to size and application

Order Flexibility

- Suitable for samples, trial batches, and production quantities

- Can be combined with LuminaTitan-supplied materials or arranged according to agreed specifications

- Each batch can be labeled with alloy/grade, size and basic ID information to support warehouse and line management

Value-Added Options (On Request)

Depending on your requirements and drawings:

- Basic deburring or simple edge treatment on cut ends

- Matching with further services via LuminaTitan network (drilling, simple machining, surface preparation)

- Documentation support such as material certificates and simple inspection records to assist international purchasing

Typical Applications

- Electrochemical & chemical equipment: titanium and alloy bars/tubes cut for anodes, manifolds and fittings

- Mechanical workshops: pre-cut blanks for CNC, reducing preparation time and off-cut waste

- Marine & offshore: corrosion-resistant bars and tubes cut to installation lengths

- OEM & project builds: small to medium runs matched to BOM lengths for easier assembly

Request a Cut-To-Length Quote

For a clear quotation, please provide:

- Alloy/grade and product form (rod/bar/tube/pipe)

- OD/size and required lengths

- Quantity (samples and/or batch requirement)

- Notes on acceptable length tolerance and edge condition

- Any documentation needs (e.g. material certs, packing marks)

Send details to sales@luminatitan.com or via the “24 Hours Quote” form. LuminaTitan will respond with practical options aligned with your project schedule.