In the field of refractory metals, achieving superior performance while ensuring cost control is paramount. We specialize in delivering high-quality refractory metal components and precision parts, which not only enhance system stability and energy efficiency but also establish solutions with technical advantages and cost competitiveness. From the crystal structure optimization of special metals like tantalum, niobium, tungsten, and molybdenum to the application of advanced manufacturing processes such as powder metallurgy and hot isostatic pressing (HIP), every component is multi-dimensionally optimized for high-temperature oxidation resistance, creep resistance strength, and full-life cycle reliability.

Whether you need material upgrades for existing equipment or customized refractory metal assemblies, our solutions meet the strict technical specifications of high-end industries such as aerospace and energy chemicals, while achieving integrated cost control across the entire supply chain.

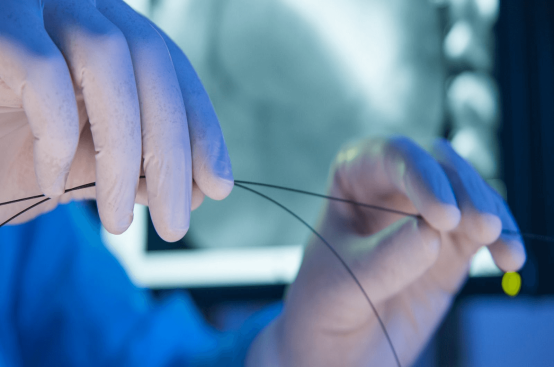

Material Positioning: ASTM F136 - certified niobium - titanium (Nb - Ti) alloy, used in orthopedic implants. PICE Implementation Details: Compliance: Meets ISO 10271 electrochemical corrosion test standards, ensuring long - term biosafety of implants. Performance Validation: Osseointegration Efficiency: The Nb₂O₅ oxide layer naturally formed on the niobium surface, verified by in - vitro cell culture experiments, can increase the osteoblast adhesion rate by 30 - 40%, helping orthopedic implants such as hip and knee prostheses achieve bone bonding more quickly. Mechanical Matching: With an elastic modulus of ~80 GPa (closer to the mechanical properties of human bone), finite element analysis data shows that compared with pure titanium alloy, it can reduce the "stress shielding" effect by 25 - 35%, reducing the risk of postoperative prosthesis loosening.